When it comes to choosing the right material for CNC machining, you’ll be spoilt for choice. Here at PT Engineers, we provide CNC machining services to a wide range of clients and industries. As a result, we have plenty of knowledge on hand to help you choose the most suitable material for your application. Whether you’re considering CNC machining plastic or you’d like to explore the metal choices on offer too, we’ll ensure you invest in the best material for the job.

So what material do you use for CNC machining? Your design for your product is custom, and you know your requirements more than anyone else. With this in mind, when deciding on the right material for your product, you should consider doing the following:

- Determine the necessary requirements for the component’s function

- Look at materials commonly used for this machined part

- Consider any secondary processes that may need to take place

- Use prototypes

Related: CNC Machining Advantages | What Are The Advantages?

CNC Machining Plastic

With CNC machining using such powerful machinery, you might be wondering whether or not you can CNC plastic. The answer to this question is yes. Plastics are often used to create moulding resins. ABS and acetal are typical CNC machining plastics but PEEK and Ultem are often the best choice for high temperature applications. Using the same resin for the desired parts as you do for the CNC machined injection moulds will give you prototypes to test on.

ABS

This is a high impact strength material. It has low heat conductivity and high mechanical strength. It also has good dimensional stability and low coefficient of friction.

Acetal

This material has high mechanical strength and low moisture absorption. Additionally, it has good dimensional stability.

PEEK

This material offers high abrasion and wear resistance. It also has low moisture absorption and low coefficient of friction.

Ultem

This has great chemical resistance and high dielectric strength, along with stiffness and fantastic strength.

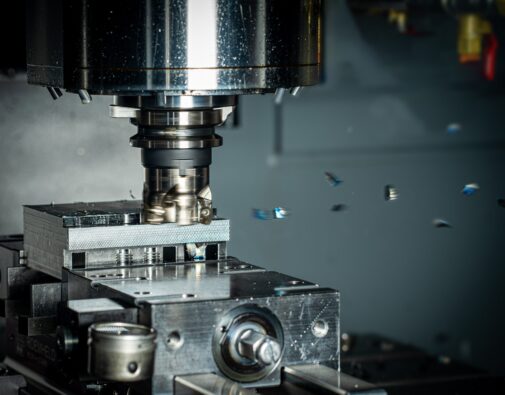

CNC Machining Metal

Can you CNC machine metal? Metals are no exception when it comes to choosing a material for CNC machining. In fact, there are some metals that are a great choice for making 3D metal parts. Metals suitable for machining must have specific mechanical properties to ensure they can withstand the process. Some of these properties include strength, flexibility, and hardness. The type of metal depends on the requirements and factors that the part needs to have, but it’s important to remember that CNC machining metal can be a little more costly.

Aluminium

Aluminium is arguably the most cost-effective metal to CNC machine. It has great machinability, is inexpensive, and has a desirable strength to weight ratio.

Stainless steel

Although it doesn’t have the same level of machinability as aluminium, stainless steel is still considered to have good machinability. It is corrosion resistant and has high electrical resistivity.

Mild steel

Usually the most common material to use in CNC machining and is the most economical material. While it has a lower tensile strength than other steels it is also the least expensive type of steel.

CNC Machining Services

If you would like support with choosing the right CNC machining plastic or metal for your project, get in touch with us today. Explore our website for more information, or call to speak to a member of our helpful and friendly team.

If you have fund this blog helpful, you may wish to read our previous blog: What Are The 5 Common Types Of CNC Machines?